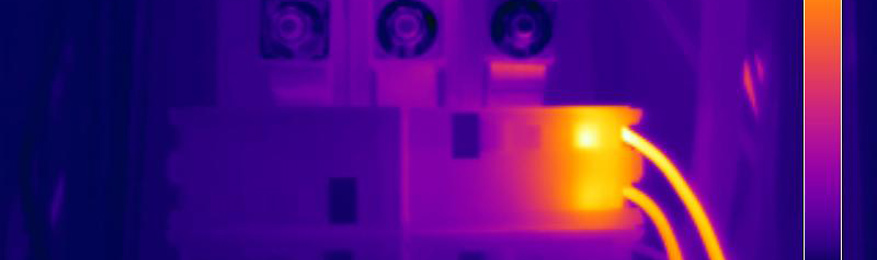

Infrared Scanning

Safety Scan

Unusual heat in your electrical and mechanical systems can lead to costly repairs and create dangerous work environments. Our electrical technicians can help protect your systems using infrared (IR) scanning to identify and correct these abnormalities.

We recommend using infrared scanning to check the following type of electrical distribution equipment:

- Utility substations, transformers and feed poles

- Main incoming services, plant main knives, capacitor banks, etc.

- Main switchboards and disconnects

- Main distribution panels and main disconnects

- Uninterruptible power supplies

- Generator controls and transfer switches

- Main I-Line panels

- Lighting and receptacle panels

- Disconnects and combination starters

- Service disconnects for motors

- Machine control panels

Our review of your system components will ensure that your workplace is safe and identify needed repairs to prevent malfunctions and system failures. Every facility manager’s preventative maintenance program should include regular infrared scans. Trust the professionals at Fleming Electric to protect your electrical and mechanical systems – we act quickly to identify any issues and provide a detailed photographic record of any problem areas to ensure proper repair.

Infrared scanning minimizes risks and saves money by preventing equipment failures and emergency repairs, reducing down time, and improving system efficiency. Equally important, infrared scanning saves time by allowing facility managers to identify and prioritize preventative maintenance and avoid disruption of operations by using non-invasive technology. Partner with our electrical technicians and project management experts to save your business time and money – and prevent catastrophic loss!

Contact us today to schedule your facility for infrared scanning!